The Toyama Monozukuri Center

Introduction | First Floor Plan | Second Floor Plan | Manufacturing | Assembly and Test | Clean Rooms | Research and Development | Community | Opening Event | Build Video

Clean Room Facilities

There are several Clean Rooms and Temperature Controlled areas making a total clean room suite of 440 m2 of floor area.

The large Class 10,000 room is designed for precise clean assembly work. A 1 tonne capacity travelling crane is located in this clean room to assist the assembly of large precision components.

The smaller Class 1,000 Clean Room leads off from the class 10,000 area. This room provides a space for ultra-clean assembly work such as is required for x-ray optical components.

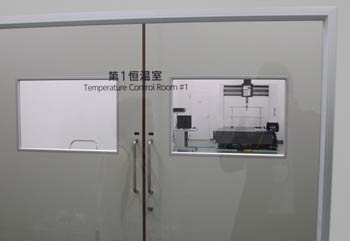

The temperature controlled clean room area is a key part of the new facility. This room has been specially designed to allow state-of-art testing of precision mechanical and optical components. The floor has been designed for high stability and this, combined with precise temperature control, provides the necessary environment. A new 3D coordinate measuring machine is also installed here.

Ultra-precision machining and measuring systems are also located in the clean room suite. The Toshiba ULC-100 ultra-precise machining center will be used for precision components such as accelerator structures. A new Zygo surface profile measuring system compliments the new precision machining facility.