New Facing Targets Sputtering System

Overview | Features | Principle | Applications | Product Information

Thin Film Properties prepared by NFTS

Features | Thin Film Properties

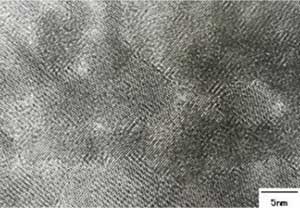

TEM image of as-deposited specimen of the Co Cr Ta films "Microstructure and noise characteristics of Co Cr Ta films on ultraflat glass substrates for longitudinal recording disk" J.Appl.Phys.87,6343(2000) ※ K.Noda,S.Kadokura and M.Nao

The magnetron sputtering (MS) methods are widely used in any thin film applications, because it is able to produce thin films across a wide area for various materials. The conventional magnetron sputtering (CMS) methods generate sputtering plasma in a space between a sputtering target and a substrate surface. Therefore the substrate surface can be directly bombarded by secondary electrons, Ar atoms and negative ions that obtain high kinetic energy at a cathode sheathe generated above the target surface, especially reactive sputtering with oxygen or nitrogen gas. As a result, the films prepared by CMS have strong internal stress, defects in grain boundary and a low density columnar structure in some cases. Furthermore, the radiation of a large amount of secondary electrons ejected from the target surface raise the temperature of the substrate surface as Joule heat.

On the other hand, the facing targets sputtering (FTS) methods use a different plasma confinement principle from CMS. FTS consists of facing targets with magnets for plasma confinement, and a substrate is positioned beside the facing targets. The sputtering plasma is confined in the space between the facing targets. Therefore the substrate surface is rarely bombarded by the particles with high kinetic energy. Additionally, secondary electrons ejected from the target surfaces are confined between the facing targets. FTS makes it possible to prepare thin films on organic materials such as organic semiconductors, Organic light emitting diode (OLED) and biomaterials that have a low heat resistance. The thin films prepared by FTS have different properties from CMS, because the thin films depositing on the substrate surface are not bombarded by the particles with high kinetic energy. Above figure shows a cross sectional view of a Co Cr Ta thin film prepared by New FTS (NFTS) observed under TEM (Transmission Electron Microscope). The TEM image shows that the film has a high density thin film structure without a defect in grain boundary.